Product Description:

Application of Vortex Flow Meter

The SKLU series vortex flowmeter is mainly used for flow measurement of industrial pipeline media fluids, such as gases, liquids, vapors, and other media. Its characteristics are small pressure loss, large range, high accuracy, and almost unaffected by parameters such as fluid density, pressure, temperature, viscosity, etc. when measuring volumetric flow rate under working conditions. No movable mechanical parts, therefore high reliability and low maintenance. The instrument parameters can remain stable for a long time. The vortex flowmeter adopts a piezoelectric stress sensor with high reliability and can operate within a temperature range of -20 ℃ to+250 ℃. It has both analog standard signals and digital pulse signal outputs, making it an ideal flow meter that can be easily used in conjunction with digital systems such as computers.

Principle of Vortex Flow Meter

When a triangular cylindrical vortex generator is set up in the fluid, regular vortices are alternately generated from both sides of the vortex generator, which are called Karman vortices. As shown in Figure 1, the vortex columns are asymmetrically arranged downstream of the vortex generator.

Schematic diagram of vortex formation

Assuming the frequency of vortex occurrence is f, the average flow velocity of the measured medium is, the width of the upstream surface of the vortex generator is d, and the diameter of the body is D, the following relationship can be obtained:

F=SrV1/d=SrV/md (1)

In the formula, V1 represents the average velocity on both sides of the vortex generator, m/s;

Sr Strouhal number;

M - The ratio of the bow shaped area on both sides of the vortex generator to the cross-sectional area of the pipeline

The volumetric flow rate qv inside the pipeline is

Qv=π D2V/4=π D2mdf/4Sr (2)

K=f/qv=[π D2md/4Sr] -1 (3)

In the formula, K represents the instrument coefficient of the flowmeter, with pulse count in m3 (P/m3).

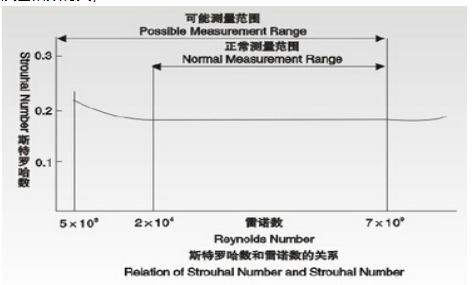

K is not only related to the geometric dimensions of the vortex generator and pipeline, but also to the Strouhal number. The Strouhal number is a dimensionless parameter that is related to the shape of the vortex generator and the Reynolds number,

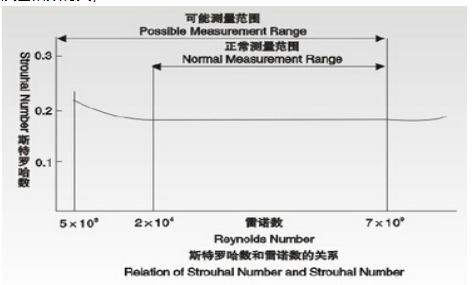

Figure 2 shows the relationship between the Strouhal number of a cylindrical vortex generator and the Reynolds number of a pipeline. As shown in the figure, Sr can be regarded as a constant within the range of ReD=2 × 104 to 7 × 106, which is the normal operating range of the instrument. When measuring gas flow rate, the flow calculation formula for VSF is (4)

Figure 2: The relationship curve between Strouhal number and Reynolds number

In the equation, qVn and qV - represent the volumetric flow rates under standard conditions (0 ℃ or 20 ℃, 101.325kPa) and operating conditions, respectively, m3/h;

Pn and P - are the absolute pressures under standard and operating conditions, respectively, Pa;

Tn and T - are the thermodynamic temperatures under standard and operating conditions, respectively, K;

Zn and Z - are the gas compression coefficients under standard and working conditions, respectively.

As can be seen from the above equation, the pulse frequency signal output by VSF is not affected by fluid properties and composition changes, that is, the instrument coefficient is only related to the shape and size of the vortex generator and pipeline within a certain Reynolds number range. However, as a flowmeter in material balance and energy measurement, it is necessary to detect mass flow rate. At this time, the output signal of the flowmeter should simultaneously monitor volume flow rate and fluid density. Fluid properties and components still have a direct impact on flow measurement.

The vortex flowmeter is a new type of flowmeter that measures fluid flow in closed pipelines based on the Karman vortex principle. Due to its excellent medium adaptability, it can directly measure the volumetric flow rate of steam, air, gas, water, and liquid without temperature and pressure compensation. Equipped with temperature and pressure sensors, it can measure the volumetric flow rate and mass flow rate under standard conditions, making it an alternative to throttling flow meters.

In order to improve the high temperature resistance and vibration resistance of vortex flow meters, an improved vortex flow sensor has been newly launched. Due to its structure and material selection, the sensor can be used in harsh working conditions such as high temperature (350 ℃) and strong vibration (≤ 1g).

In practical applications, the maximum flow rate is often much lower than the upper limit of the instrument, and with changes in load, the minimum flow rate is often lower than the lower limit of the instrument. The instrument is not working in its optimal working range. To solve this problem, it is usually necessary to reduce the diameter at the measuring point to increase the flow rate at the measuring point, and use smaller diameter instruments to facilitate the measurement of the instrument. However, this variable diameter method requires a straight pipe section with a length of more than 15D between the variable diameter pipe and the instrument for rectification, which makes processing and installation inconvenient. The LGZ variable diameter rectifier with a curved longitudinal section has multiple functions such as rectification, increasing flow velocity, and changing flow velocity distribution. Its structural size is small, only one-third of the inner diameter of the process pipe, and it is integrated with the vortex flowmeter. It not only does not require an additional straight pipe section, but also reduces the requirements for the straight pipe section of the process pipe, making installation very convenient.

For the convenience of use, the battery powered local display vortex flowmeter adopts micro power consumption technology. It can operate continuously for more than a year with lithium battery power supply, saving the procurement and installation costs of cables and display instruments. It can display instantaneous flow, cumulative flow, etc. on site. The temperature compensated integrated vortex flowmeter also comes with a temperature sensor, which can directly measure the temperature of saturated steam and calculate the pressure, thereby displaying the mass flow rate of saturated steam. The temperature pressure compensation integrated type is equipped with temperature and pressure sensors, which can directly measure the temperature and pressure of the gas medium for gas flow measurement, thereby displaying the standard volume flow rate of the gas.

Measurement medium: gas, liquid, vapor

◆ Caliber specification: Flange card type caliber selection: DN15~300

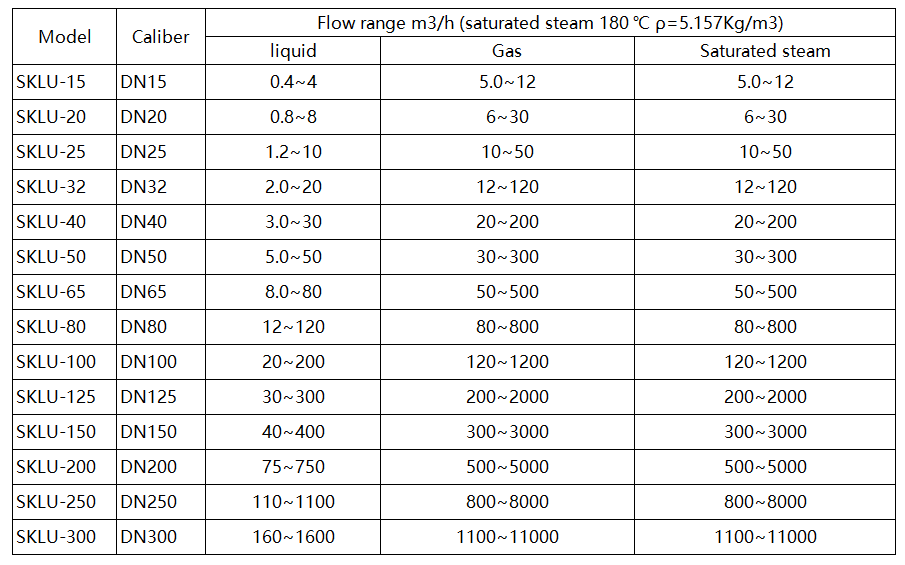

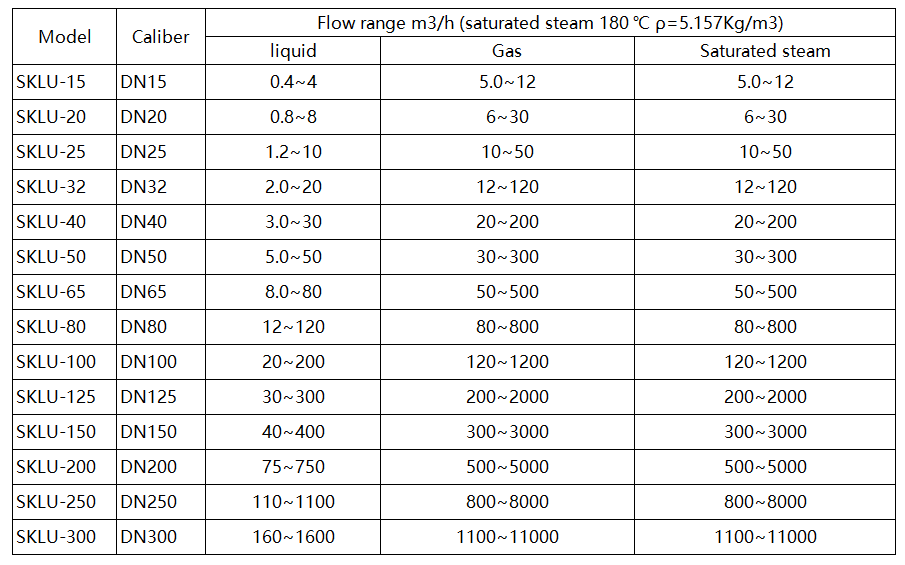

◆ Flow measurement range Normal measurement flow velocity range Reynolds number 1.5 × 104~4 × 106; Gas velocity of 5-50m/s; Liquid 0.5-7m/s

The normal measurement range for liquid and gas flow is shown in Table 2; The steam flow range is shown in Table 3

Measurement accuracy: Level 1.0, Level 1.5, Level 2.5

◆ Temperature of the tested medium: normal temperature -25 ℃~100 ℃

◆ High temperature -25 ℃~150 ℃ -25 ℃~250 ℃

Output signal pulse voltage output signal high level 8-10V low level 0.7-1.3V

The pulse duty cycle is about 50%, and the transmission distance is 100m

Pulse current remote transmission signal 4-20 mA, transmission distance of 1000m

◆ Instrument operating environment temperature: -25 ℃~+55 ℃ humidity: 5-90% RH50 ℃

◆ Material: Stainless steel, aluminum alloy

◆ Power supply DC24V or lithium battery 3.6V

Explosion proof grade: EXdbIICT6Gb

◆ Protection level IP65

Product selection of vortex flowmeter

| Code | Function 1 |

| N | No temperature and pressure compensation |

| Y | Temperature and pressure compensation |

| Code | Output signal |

| F1 | 4-20mA output (two-wire system) |

| F2 | Pulse |

| F3 | RS485communication interface |

| F4 | HARTprotocol |

| Code | Measured media |

| J1 | liquid |

| J2 | Gas |

| J3 | Steam |

| Code | Connection method |

| L1 | Flange card installation type |

| L2 | Flange connection type |

| Code | Function 2 |

| E1 | Level 1.0 (applicable to liquids) |

| E2 | Level 1.5 |

| E3 | Level 2.5(DN15 DN20) |

| Normal temperature |

| High temperature |

| Steam |

| P1 | 1.6MPa |

| P2 | 2.5MPa |

| P3 | 4.0MPa |

| D1 | Internal 3.6V power supply (without output) |

| D2 | DC24V power supply |

| B1 | Stainless steel (flange material) |

| B2 | Carbon steel (flange material) |

The vortex flowmeter series products include: plug-in vortex flowmeter; Gas vortex flowmeter; Steam vortex flowmeter; Integrated vortex flowmeter with temperature and pressure compensation